Using Additive Manufacturing for Rapid Prototyping

March 22, 2023

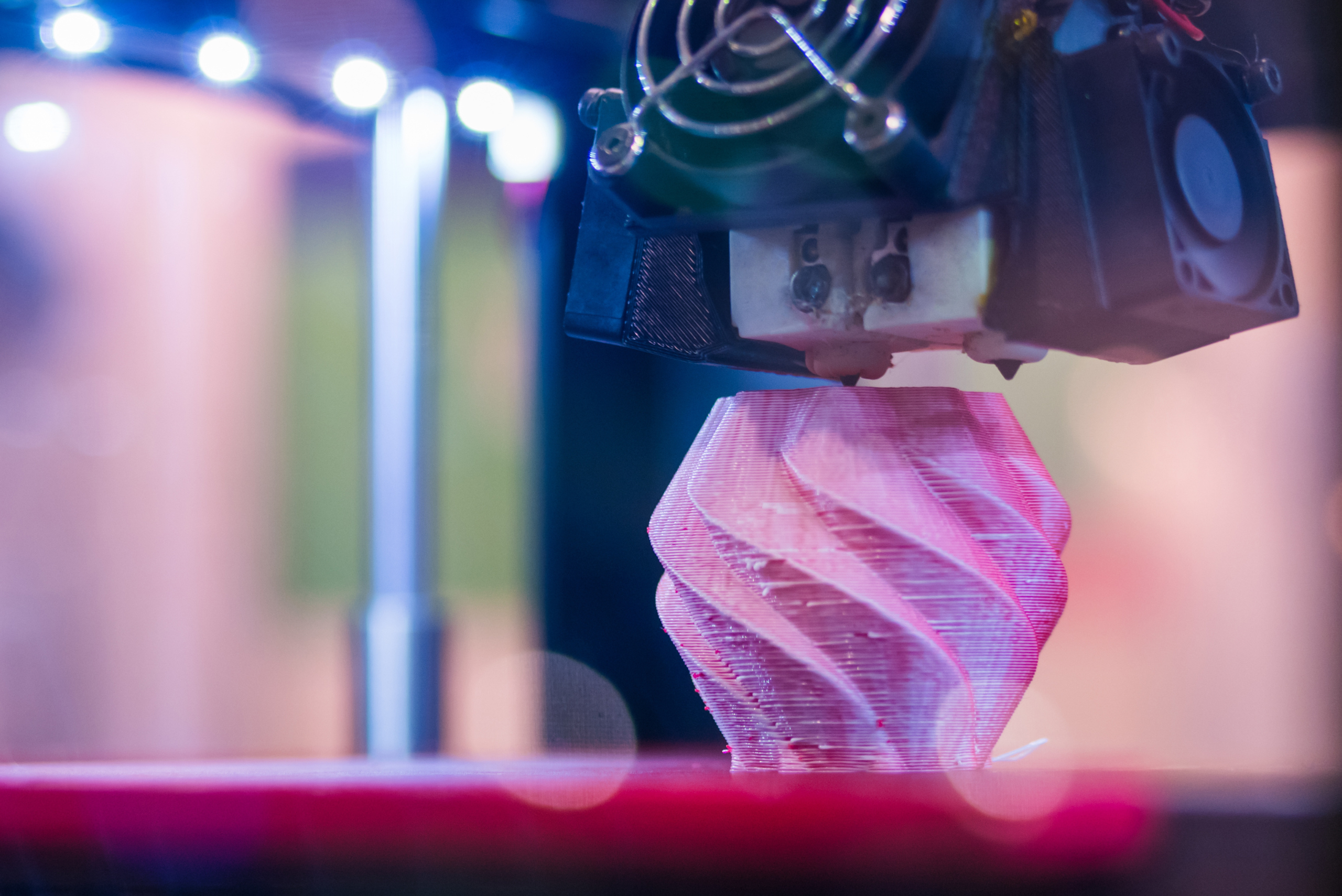

Additive manufacturing, also known as 3D printing, can trace back it’s origins to the 80s.

Industrial technology has always played a critical role in the defense sector. In recent years, additive manufacturing has begun to play an even more critical role in weapon design and prototype development. This is due to the many advantages that additive manufacturing offers over traditional manufacturing methods.

In this article, we will take a look at how additive manufacturing is changing the way military technology is designed and produced.

What Is Additive Manufacturing?

Additive manufacturing is a manufacturing process that creates objects by successively adding layers of material. Unlike traditional subtractive manufacturing processes, which start with a larger piece of material and remove the excess to create the desired shape, additive manufacturing builds an object from the ground up, layer by layer.

This gives additive manufacturing the ability to create highly complex shapes that would be impossible to create with traditional manufacturing methods. Additive manufacturing has been used in a variety of applications ranging from weapon design to medical implants.

However, the most common use for additive manufacturing is rapid prototyping. Rapid prototyping is a process in which engineers can quickly create prototypes of new products without the need for expensive tooling or molds. This helps to speed up the product development cycle and get new products to market faster.

Why Is It Important in Military Designs?

In weapon design, additive manufacturing (AM) is a process of creating three-dimensional objects by successively adding layer upon layer of material. AM is important in weapon design because it offers several advantages over traditional manufacturing methods, such as:

- Milling

- Lathing

- Stamping

First, AM can create complex shapes that would be impossible to create using traditional methods. AM can also fabricate parts with very tight tolerances, which is critical in weapon design where even small discrepancies can have a major impact on performance.

AM can produce parts with very high levels of detail and surface finish, which is important for both aesthetics and function. Finally, AM allows for the creation of custom parts without the need for expensive tooling or dyes.

As a result, additive manufacturing is becoming an increasingly important technology in military designs.

Additive Manufacturing vs. Traditional Methods: A Comparison

The process of building products by adding layers allows for the creation of complex shapes that would be difficult or impossible to produce using traditional machining methods. In addition, AM can create products with multiple materials and colors.

However, one of the main limitations of additive manufacturing is its speed. The process of building an object layer by layer is much slower than other methods such as milling or injection molding. In addition, additive manufacturing often requires special equipment and materials, which can add to the cost of production.

Traditional manufacturing methods such as milling or injection molding involve removing material from a larger piece to create the desired shape. These techniques are much faster than additive manufacturing with a wide range of materials.

Traditional methods are limited by the fact that they can only produce objects with relatively simple shapes. In addition, it can be difficult to produce products with multiple colors or materials using traditional techniques.

The Benefits of Additive Manufacturing in the Defense Sector

In the defense sector, AM provides an opportunity to create complex weapons and weapon components that would be difficult to produce using traditional manufacturing techniques. AM also allows for the quick prototype design and testing of new products, with less need for expensive tooling or molds.

In addition, parts produced through additive manufacturing often have:

- Higher levels of detail

- Surface finish

- Dimensional accuracy

Cost-Effectiveness

One of the primary benefits of additive manufacturing in the defense sector is its cost-effectiveness. While we are not yet at the stage where we can use 3D printing on a large-scale production, it does greatly decrease the cost of prototype design.

The prototype design process often costs companies and contractors up to 80% of the research and development costs.

Additionally, additive manufacturing often requires less material than traditional manufacturing, which can further reduce costs.

Increased Efficiency

Additive manufacturing also offers increased efficiency in the production of defense-related parts and components.

Additive manufacturing technology allows for the production of parts and components with very tight tolerances, which can improve the performance of finished products. Additionally, additive manufacturing often eliminates the need for secondary machining operations.

Customization

Another benefit of additive manufacturing in the defense sector is its ability to produce customized parts and components.

Additive manufacturing technology allows for the production of parts and components with unique geometries that cannot be created using traditional manufacturing methods. This capability can be particularly beneficial in the development of new and innovative products.

Weight Reduction

Additively manufactured parts and components often weigh less than their traditionally manufactured counterparts. This weight reduction can lead to significant reductions in fuel consumption, which can improve the range and endurance of military vehicles and aircraft.

Lighter-weight components can also reduce wear and tear on vehicles and equipment, leading to increased lifespan.

How Additive Manufacturing Is Changing the Designs of Prototype Weapons

In the past, product designers were limited by the manufacturing process when it came to prototype design. If a product couldn’t be manufactured using traditional methods, it would be either impossible or too expensive to produce.

However, additive manufacturing has changed the game by making it possible to create complex prototypes quickly and affordably. As a result, designers are now able to experiment with innovative new military designs that wouldn’t have been possible before.

One example is the M17 Modular Handgun System, which was created using additive manufacturing techniques. The modular design of the gun allows for greater customization and easier maintenance, and the use of 3D-printed parts makes it more lightweight and durable than traditional pistols.

In addition, additive manufacturing has also allowed for the creation of new types of ammunition, such as “smart” bullets that can adjust their course in mid-flight. As additive manufacturing technology continues to advance, we can expect to see even more amazing military technology in the future.

Challenges Using Additive Manufacturing in Weapon Design

Despite the many benefits of additive manufacturing for military technology, there are still some challenges associated with its use. One issue is that technology can be expensive, as well as the materials required for 3D printing.

Below, you will find some more challenges the industry faces.

Industrial Technology

Additive manufacturing has been used extensively in the medical and automotive industries, but there are challenges when using additive manufacturing for military technology.

One challenge is that most 3D printers are still in the early stages of printing metal, which is the material most weapons are made of. As a result, it can be difficult to find a printer that can meet the specific requirements of weapon design. Additionally, the cost of 3D printers is another barrier to entry. However, as additive manufacturing technology continues to develop, these challenges will likely be overcome.

Qualifications and Certifications

One of the most important considerations in military designs is the type of materials used. The choice of materials can have a significant impact on the performance of the technology, as well as its:

- Weight

- Costs

- Durability

Additive manufacturing offers the potential to create weapons using a wide range of materials, including:

- Metals

- Plastics

- Composites

However, there are challenges associated with using additive manufacturing in military technology.

First, the rigorous standards of military technology designs require that materials meet high standards for strength, durability, and performance. This can be difficult to achieve with additive manufacturing.

Additive manufactured parts often require special qualifications and certifications due to the unique nature of their production. This can add cost and time to the weapon design process.

There is also a lack of standardization in additive manufacturing, which can make it difficult to produce consistent results. Finally, additive manufacturing is still a relatively new technology, and there is limited experience using it in weapon design.

Still, additive manufacturing offers great potential for military technology designers who are looking to create new and innovative weapons.

Economical Challenges

The development of additive manufacturing technology has led to new challenges in technology design. Another big challenge is the economics of 3D printing. While 3D printing is generally cheaper than traditional manufacturing methods, it is not always cost-effective for large-scale production.

This means that technology designers must carefully consider the cost implications of using 3d printing in their designs. Another challenge is the need for highly specialized skills and knowledge.

Because additive manufacturing is a relatively new technology, there is a shortage of qualified professionals who can operate 3d printers and produce quality components.

This lack of qualified personnel can lead to delays in production and increased costs. Despite these challenges, additive manufacturing is a potentially transformative technology that could revolutionize military technology design.

The Future of Additive Manufacturing in Military Design

Additive manufacturing has tremendous potential for military advancement, and the technology is already being used in some areas.

In the future, additive manufacturing could enable technology designers to prototype weapons quickly and cheaply, allowing for more rapid iteration of designs. Additionally, additive manufacturing could allow for the production of stronger and lighter weapons, as well as weapons with more complex geometry.

Finally, due to the increased efficiency, more contracts become available in additive manufacturing, opening up a new door for contractors interested in weapon design.

Below, we will look at some other trends we can expect to see in the following years.

Increased Accuracy

Additive manufacturing technology has the potential to increase the accuracy of designs. This is because additive manufacturing can create complex shapes that traditional machining methods cannot. This means that weapons can be designed with tighter tolerances, which can improve their accuracy.

Improved Durability

Additive manufacturing can also improve the durability of designs.

This is because additively manufactured parts are typically stronger than those made with traditional machining methods. This means that weapons made with additive manufacturing technology will be able to withstand more wear and tear, and will be less likely to break or malfunction.

Customization

Another benefit of additive manufacturing in technology design is customization.

Additive manufacturing allows for the creation of customized parts and components, which means that gear can be designed specifically for each user. This level of customization can improve the effectiveness of the gear and make them more user-friendly.

Cost Savings

Additive manufacturing also has the potential to save money in military technology designs. This is because additive manufacturing can reduce the need for expensive tooling and machining operations.

Additionally, additively manufactured parts often require less material than traditional parts, which can further reduce costs.

Faster Production Times

Finally, additive manufacturing has the potential to reduce production times for military technology designs. This is because additive manufacturing can produce parts and components much faster than traditional machining methods.

This means that weapons can be designed and produced in a shorter time frame, which can be critical in military applications.

Additive Manufacturing: Innovative Military Technology Designs

Additive manufacturing technology has the potential to revolutionize military gear and technology, and the defense industry is taking notice. Several government agencies have already begun to invest in additive manufacturing technology, and this trend is likely to continue in the years ahead.

The benefits of additive manufacturing are numerous and include faster production times, improved durability, increased accuracy, and reduced costs. Additive manufacturing has the potential to change the way weapons are designed and produced, making them more effective and affordable.